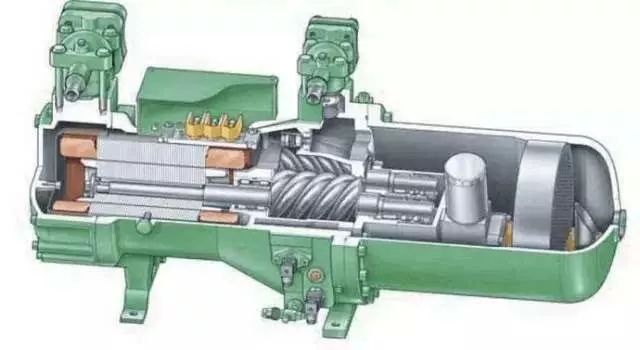

A, ku-screw compressor ukwehluleka, ukuqeda ukwehluleka uwoyela kuyinto evame kakhulu, ebangela ukugcwala ngokuhluleka uwoyela kwezinto eziphambili:

1

Ekusebenzeni kwesikulufa compressor, umnyombo wokuhlukanisa kawoyela owonakalisiwe njengento ephukile, ye-pernomenon ephukile, khona-ke ilahlekelwa yindima yokwehlukana kwamafutha negesi. Lokho wukuthi, igesi exubekile kanye ne-compressor eqeda amapayipi ngqo, khona-ke inani elikhulu lamafutha okupholisa alihlukaniswanga, lizokhishwa ngomzimba wegesi, okuholela ekuhlulekeni kwamafutha.

I-2.oil Return Return ukwehluleka

Enqubweni yokusebenza ye-compressor yesikulufa, ama-oyela abuya emugqeni wemfanelo obalulekile, indawo yokuhlukaniswa kawoyela ezokwakha umehluko wengcindezi, endimeni yalomngcwabo, insizakalo yokubuyiselwa kwamafutha ebhekiswe engxenyeni ebunjiwe emuva ku-compressor, kwinqubo elandelayo yomjikelezo iyaqhubeka nokusebenzisa. Uma umugqa wokubuya kawoyela uvinjelwe, ephukile futhi efakwe ngokungalungile, ngeke ikwazi ukuthutha uwoyela oqoqwe phansi kokonakala okubuyiselwe emuva ku-compressor, bese kuba khona uwoyela omningi ozokhishwa ngegesi, futhi kuzoba khona into yamafutha kwinqubo yokuphelelwa yisikhathi.

3. Ukulawulwa kwengcindezi yohlelo kuphansi kakhulu

Ekusebenzeni kwe-compressor yesikulufa, ukulawulwa kwengcindezi yesistimu kuphansi kakhulu, kuzodala ukuthi amandla we-centrifugal ku-degrest angaphansi komsebenzi odingekayo, kungaphezulu kwengxenye yawo ehlukanisiwe, futhi kuholele ekuhlukaniseni uwoyela kanye nokwahlukaniswa kwegesi ngaphandle kokuhluleka kwe-compressor.

4.Ukuhluleka kwengcindezi ye-valve valve

Ekusebenzeni kwe-compressor yesikulufa, i-sumthen gressure valve ukuqinisekisa ukuthi ukusebenza kwengcindezi yohlelo lokulawula ukulandelwa kwengcindezi encane ngenhla. Uma ubuncane bengcindezi yengcindezi yokwehluleka kwe-valve valve, khona-ke ukucindezela okuncane kohlelo ngeke kuqinisekiswe, ngenxa yenhlanhla yemishini kungukusebenzisa kakhulu igesi, kuzodala ukuthi umfutho wesistimu uphansi kakhulu, umugqa wokubuyiselwa kwamafutha awukwazi ukubuyisa uwoyela. Amafutha aqoqwe phansi kombango ohlukanisayo wamafutha ngeke akwazi ukubuyela ku-compressor, azokhishwa ku-compressor ngegesi ecindezelwe, okuholela ekuhlulekeni kwamafutha.

5.UCompressor ukujoyina uwoyela opholile kakhulu

Ngaphambi kokusebenza kwe-compressor yesikulufa, engeza kawoyela okupholisa kakhulu, ngaphezu kohlu lwe-compressor, khona-ke lapho kukhishwa igesi, ngenxa yokuphuma kwegesi, ngenxa yokukhishwa kwegesi, okubangelwa ukukhishwa kwegesi okuqukethe uwoyela omningi, ngokuhluleka uwoyela.

6.Ikhwalithi yamafutha okupholisa awenzi kahle

Ngaphambi kokusebenza kwe-compressor, ukungezwa kwamafutha okupholisa angenakulinganiswa, noma uwoyela wokupholisa ngaphezu kwesikhathi esisebenzayo, akukwazanga ukufeza umphumela wokupholisa. Lapho-ke ekusebenzeni kwe-compressor yesikulufa, amafutha apholile alahlekelwe indima yawo, futhi awakwazi ukupholisa ukuhlukaniswa kwamafutha kanye negesi. Lapho-ke kwinqubo yokuphuma ngokuqinisekile izovela ngokwehluleka kawoyela.

Okwesibili, isheke lephutha, izinyathelo zokuxazulula inkinga

Lapho i-compressor itholakala ngamafutha ku-adport, akudingeki ukuthi ihlukanise ngokungaboni imishini, kepha kufanele isuselwe kulezi zizathu ezingenhla zokuhlaziywa, ngokuya ngezinyathelo ezivela kunzima ukuthola izingxenye zephutha. Lokhu kunganciphisa isikhathi esiningi sokulungiswa kanye namandla.

Lapho i-compressor iqala ngokujwayelekile futhi uhlelo lufinyelela ingcindezi ekalwe, vula kancane kancane i-valve yesango lokuphenya, ukuvulwa kufanele kube okuncane ngangokunokwenzeka ukuvumela inani elincane legesi ukubalekela. Ngalesi sikhathi, sebenzisa ithawula lephepha elomile ngokumelene ne-airflow eqeda umoya, uma ithawula lephepha lihlanjululwe futhi amaconsi kawoyela, unganquma ukuqeda amandla okuqeda amandla. Ngokuya ngenani lamafutha egesi yokuphelelwa yisikhathi kanye nezikhathi ezihlukile zesikhathi, njll., Ukwahlulela okulungile kungenziwa engxenyeni lapho kwenzeka khona iphutha.

Lapho ukuvulwa kwe-exform cant valve kukhuphuke, ukukhishwa komoya kutholakala kungukuphazamiseka okungachithwa, okukhombisa ukuthi i-airflow iqukethe uwoyela omningi, bese ubheka ubuyela oo kawoyela buyele ku-oyela return tube! Uma i-oyili yokubuya ishubhu isibuko sokubuyiselwa kowoyela ukubuyiselwa kwamafutha kukhuphuke kakhulu, ngokuvamile kumafutha ahlukanisiwe aqhekekile noma owesigaba sokupholisa ongezelwe kakhulu; Uma i-oyili ibuya ishubhu isibuko akukho ukubuya kwamafutha, ngokuvamile ku-oyili yokubuyisa ishubhu ephukile, ivinjiwe.

Lapho isango lokuphelelisa likhulisa ukuvulwa, lithole ukuthi ingxenye yangaphambili yokuphuma komoya kuyinkungu okuminyene, ngemuva kwesikhathi nokujwayelekile; Qhubeka nokwandisa ukuvulwa kwe-valve yesango lokuphenya, yonke i-valve ephelayo, khona-ke bheka i-System Pressure Gauge, uma ingcindezi yengcindezi ibonisa ukuthi ingcindezi iphansi kakhulu kunengcindezi yokucindezela okuncane kwengcindezi, i-valve ekhipha umoya iyaqhubeka nokuphelelwa yinkungu. Le nto yenzeka, iphutha ngokuvamile ukwehluleka kwe-valve valve.

Lapho ukuvalwa okujwayelekile, i-valve yokungena ngokuzenzakalela, uma ukuqedwa kwenani elikhulu lamafutha, okukhombisa ukuthi i-valve yokuzitholela ezenzakalelayo yonakele.

Okwesithathu, ukwehluleka okuvamile ukuphakamisa izindlela

Screw Compressor ekusebenzeni kwe-occoud enamafutha asezinhlelweni zokwehluleka yizizathu ezahlukahlukene, izizathu ezihlukile zidinga izindlela ezahlukahlukene zokuxazulula.

1.OIX Ukuhlukanisa Inkinga

Umonakalo we-oyela wohlukaniso uyisimo esivamile, ngakho-ke ku-compressor yesikulufa ngaphambi kokuhlolwa kwemishini kudingeka ukuthi ihlolwe, ukusetshenziswa kwenqubo kufanele kube ngokuqinile ngezinqubo zokusebenza, ngemuva kokusetshenziswa njalo kwemishini. Kutholakale ukuthi umnyombo wokuhlukanisa kawoyela wephukile futhi wenziwa ngokweqile, kufanele athathelwe indawo ngesikhathi esifanele sokuqinisekisa ukusebenza okujwayelekile kwemishini.

2.Problems endleleni yokubuya kawoyela

Enqubweni yokusebenza kwemishini, uma uhlangabezana nokuvinjwa endleleni yokubuya kawoyela, udinga ukubheka ukwehla kwengcindezi kohlukanisi, njengokucindezela kwengcindezi ngaphandle kwezinkinga kudingeka uhlanze ngendlela efanelekile kufanele kuthathelwe indawo ngesikhathi esifanele.

I-3.System Pressure Control Great Tool

Ku-opharetha, kufanele ujwayelene nengcindezi yokulawula yemishini, lapho inkinga itholakala ukuthi inciphise umthwalo wohlelo, ukuze kucindezelwe uhlelo lokuthola ingcindezi yokusebenza ekalwe.

4

Ekusebenzeni kwangempela, uma i-valve yengcindezi yobuncane itholakala ingavumelekile, khona-ke kufanele ithathelwe indawo, bese isebenza ngemuva kokuqedwa esikhundleni sekuqediwe.

5. Inkinga yokwengeza uwoyela wokupholisa kakhulu ku-compressor

Lapho ungeza uwoyela wokupholisa ku-compressor kufanele aqonde kuqala inani le-theoretical yokuthi malini amafutha okupholisa kufanele angezwe kumishini, okungeziwe kwamafutha okupholisa kufanele kube umthwalo wemfanelo wengilazi ebona ingilazi.

U-Meshwality Wokupholisa Amafutha

Ukuze ukwengezwa kwamafutha okupholisa kufanele kwengezwe ngokuhambisana nezidingo zemishini emafutheni apholile, ngoba izidingo zemishini ehlukene kumafutha apholile azifani. Ngemuva kokungeza, isikhathi sokungezwa kufanele siqoshwe, futhi lapho uwoyela opholile efinyelela empilweni yawo yenkonzo, kufanele ushintshwe ngesikhathi. Izinga lamafutha okupholisa angeziwe kufanele lilawulwe ngokuqinile ukuze uqede ukwengezwa kwamafutha okupholisa angafanele.

Okwesine, Ukuxazulula inkinga kanye namanothi wesixazululo

Ngenqubo yokuxazulula inkinga Kunamaphoyinti amaningana okufanele aphawule, ngaphandle kwalokho iphutha akukhona kuphela ukungaqediwe, kepha kungaholela emiphumeleni emikhulu.

Uma kwahlulelwa ukuthi kuyinkinga yepayipi lokubuya, ipayipi lokubuya lingahlanzwa futhi livinjelwe noma liphinde lifakwe. Kule nqubo kufanele anake: Okokuqala, kufanele aqinisekise ukuthi iphayiphu yokubuya kawoyela ibushelelezi, hhayi ngenxa yokushiswa kwe-welding ukwenza ububanzi bepayipi libe lincane; Okwesibili, isikhundla sokufaka sepayipi lokubuya kawoyela kumele sibe selilungile, ngokuvamile isikhungo esingezansi se-ahlukanise concave concave eyisisekelo negebe phakathi kokuphela kwepayipi elibuyayo kawoyela ngo-3 ~ 4mm.

Uma kwahlulelwa ukuthi umnyombo wehlukanisile uyinkinga, kuphela i-New Supsaring Core engashintshwa. Kule nqubo kufanele anake: Okokuqala, ukubheka ngokucophelela ukuthi umnyombo omusha wehlukanisile ukhubazekile futhi onakele; Okwesibili, ukwenza umsebenzi ohlanzekile wokuhlanza indawo yokuhlanganisa yesilinda sesihlukanisi nesembozo esiphezulu; Ekugcineni, ukufakwa kufanele kufanele kuhlole ukuthi ngabe kunezinto zensimbi kanye nezinye izidumbu eziphambukayo Pad Pad Pad PAD PAD PAD phezulu, ngoba uwoyela opholile ujikeleza ngesivinini esikhulu ngaphakathi kohlukanisi, futhi inani elikhulu le-tatuct kagesi lizokwenziwa kwi-Corerast Core.

Uma kwahlulelwa ukuthi kuyinkinga yezinga lamafutha ahlukanise ngokweqile, kufanele likhishwe kahle. Hlola izinga lamafutha ahlukanisayo ngendlela efanele, okokuqala, iyunithi kumele lipake, uma i-engela evunta iyunithi likhulu kakhulu, ukuboniswa kwemitha ye-oyela ku-Upredings ku-Uhlukanisi akulungile; Okwesibili, isikhathi sokuhlola kufanelekile ukukhetha ngaphambi kokushayela noma ngemuva kwesigamu sehora lokuvalwa.

Yize i-compressor yesikulufa iyisibonelo esithembeke kakhulu, kepha ayidingi ukulungiswa nokulungiswa. Kumele wazi ukuthi noma yiziphi izinto 'zingamaphuzu amathathu ekusetshenzisweni, amaphuzu ayisikhombisa ekugcinweni ", ngakho-ke, noma ngabe amafutha okuphelelwa amandla noma amanye amaphutha, kufanele aqinise ukusebenza komsebenzi wokulungisa, iphutha lizoqedwa ku-bud.

Isikhathi sePosi: Meyi-26-2023