Embonini wefriji, izidingo zobuchwepheshe eziphansi kakhulu zamaphaneli okugcina amakhaza adonsele inani elikhulu labasebenzi kanye nokutshala imali enkulu. Ibhodi lokugcina elibandayo libaluleke kakhulu kwisitoreji esibandayo, ngoba isitoreji esibandayo sehlukile kwi-Warehouse ejwayelekile, izinga lokushisa ngaphakathi kwesitoreji esibandayo livame ukwehlisa, futhi ngokushisa komoya, kanye nezidingo zezemvelo ziphezulu.

Ngakho-ke, lapho sikhetha ibhodi yokugcina ebandayo, kufanele sinake ukulawulwa kwezinga lokushisa kwebhodi lokugcina elibandayo, uma ukukhethwa kwebhodi elibandayo kungahambi kahle, noma ukuvumela ukugcinwa kwesikhashana okugcinwe ku-compressional ngaphakathi, ukuchitha izinsizakusebenza eziningi kanye nezindleko eziningi. Ukukhetha iphaneli elifanele kuyindlela engcono kakhulu yokugcina isitoreji esibandayo.

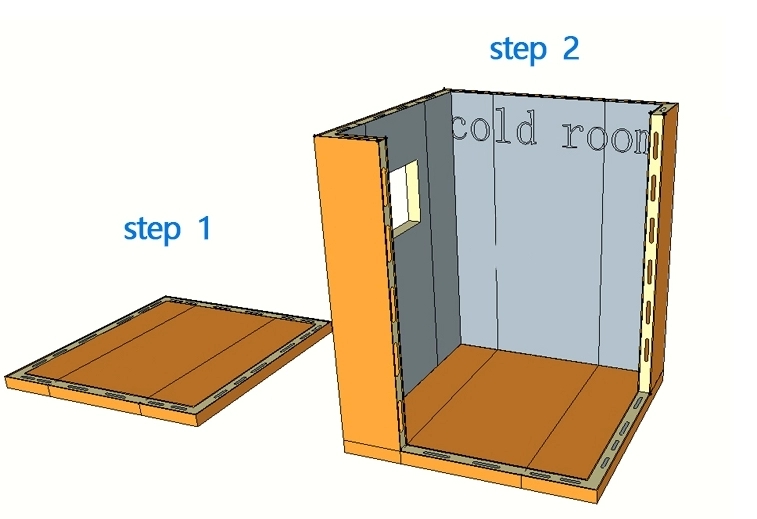

Namuhla, sizogxila kakhulu ezicini ezintathu zokufakwa kwephaneli yokugcina ebandayo: Ukufakwa kwephaneli yodonga, ukufakwa kwephaneli yophasi kanye nokufakwa kwephaneli ekhoneni.

Ngaphambi kokufakwa kwesitoreji esibandayo Sidinga ukwenza umsebenzi ohambelana nalokhu, njengoba isisho sihamba, umsebenzi muhle emsebenzini wawo kumele uzuze kuqala amathuluzi awo, kufanele kube ngokuqinile ukuze wakhe isitoreji esihle kakhulu. Imishini yokugcina ebandayo ifaka cishe: Amaphaneli okugcina amakhaza, iminyango, amayunithi okuqapha, amabhokisi okulawula, ama-valves e-cobrary, ama-sealants, izibani zekholishi, futhi nezinto ezijwayelekile.

Lapho uhambisa, kuyadingeka ukuthatha kancane, futhi wenze umsebenzi omuhle wezindlela zokulwa nokwenziwa emhlabathini. Ekufakweni kwepuleti kudinga ukufakwa ngokuqinile ngokuya ngemidwebo ye-Design, kuhle ngaphambi kokufakwa kwepuleti ukwenza inombolo enhle, ukuze ihlelwe ngokwengeziwe. Isitoreji esibandayo kufanele sifakwe ngezindonga ezizungezile, ophahleni, njll. Ukushiya ibanga elithile, ukuqinisekisa ubushelelezi bomhlaba, njengesitoreji esikhulu esibandayo kudingeka wenze umsebenzi omuhle wokuthola umsebenzi ngaphambi kwesikhathi. Uma kukhona ama-slits phakathi kwamaphaneli, i-sealant kufanele isetshenziselwe ukuqinisekisa ngokuqinile ukusebenza kwe-thermal insulation kwamaphaneli futhi kunciphise ukwenzeka komoya ohamba ngento egijimayo. Ngemuva kokufakwa kwamaphaneli ekhondweni ngalinye, udinga ukusebenzisa izingwegwe zokukhiya ukuze ulungisene ukuze ulondoloze ubuqotho besitoreji esibandayo buwonke.

一. Ukufakwa kwephaneli yodonga

1, ukufakwa kwephaneli yodonga kufanele kuqalwe ekhoneni. Ngokuya nge-Plate-Laying DIAGRAM, amabhodi amabili adinga ukufakwa emakhoneni esizeni sokufaka, ngokuya ngokuphakama kwebhodi le-nylon ephakeme, ukushayela kwe-engle irobhothi amakhowe ekhanda lebhodi, umgodi ku-heather head nylon bolts (i-nylon bolt body kanye namakhowe Ikhanda kufanele livalwe ngokunamathisela uphawu), isethwe e-angle iron ukuqinisa, qinisa iziqu ze-nylon bolts ukwenza ingaphezulu lebhodi ukucindezelwa okuncane kufanelekile. Lapho umile ebhodini lodonga, kufanele lixhumane ne-groove yaphansi yebhodi elihlanganisiwe ngegwebu nezinye izinto ezithambile ukuvikela ukulimala kwebhodi, bese uhlola ukuphakama okuphezulu kwebhodi eliphansi, kufanele kuhlolwe phezulu kwebhodi eliphansi, kuqondile kusukela ekuqaleni kudingeka ukuthi uhlole). Ngemuva kwesikhundla esifanele sepuleti sodonga, izingcezu zensimbi ye-angle zizofakwa engxenyeni yepuleti, zilungiswe ngaphakathi nangaphandle kwekhoneni lephakeji (ipuleti ekhoneni lephakeji kuzo zombili izinhlangothi ze-Library Board zokuxhumana nokuxhumana ne-Tabrary Board yoMtabhory ukuze udlale unamathisela uphawu). Ezingxenyeni ze-welding angle iron, kufanele imbozwe ngesihlangu ekhoneni izinsimbi zensimbi yepuleti yokugcina, ukuvikela i-arc welding lapho izinga lokushisa eliphakeme lokushisa lishisa ipuleti yokugcina izimpahla kanye ne-welding slag splash epuleti lokugcina izimpahla.

2, ngemuva kokufakwa kwamaphaneli amabili odonga ekhoneni, qala ukufaka iphaneli elandelayo yodonga eceleni kwekhoneni. Ipuleti elilandelayo elidongeni kufanele lifakwe ngaphambi kokuba libe ne-convex groove noma i-groove yeBhodi ukuze lidlale uphawu lokubopha uphawu lwe-convex (ukudlala uphawu lwe-convex noma i-groove

I-3, phakathi kwale bhodi emibili yetabhulali kuqala nesando ukushaya i-pad ebhodini le-polyurethane library kule ndawo izinkuni, ukuze ibhodi nelebhodi lisondele ndawonye. Amasethi amabili wezixhumi ahlukaniswa phakathi kwepuleti yodonga nepuleti yodonga, futhi amasethi amabili ezixhumeke ahlelwe ngaphandle nangaphakathi kweplanethi yodonga kanye ne-Insitate ye-Wall, futhi izixhumi ezingaphakathi kwepulangwe kufanele zifike kude kakhulu ukuze ukhonkolo ikwazi ukumboza izixhumi ngemuva kokuthela. Igebe phakathi kweBhodi neBhodi kufanele ligcinwe cishe nge-3mm ububanzi ngemuva kokushada nezixhumi, uma kungahlangabezana nezidingo zenuzi, iBhodi lizosuswa, bese igebe lebhodi lizophinde lilungiswe ukuze lihlangabezane nezidingo. Lapho silungisa isixhumi, kufanele sinake izingxenye ezimbili zeqoqo lezixhumi zilungisiwe onqenqemeni lwe-convex kanye nama-rivets amabili, ama-rivets amabili, ibanga lesixhumi ukuze likwazi ukudonsa amapuleti amabili ngokuqinile. Lapho wehlisa i-wedge yensimbi, i-hammer and wedge iron ukuze ulondoloze ukumpondo, gwema ukuthinta ibhodi, izingxenye ezingenhla zensimbi ye-wedge kufanele ziganwe ngasikhathi sinye, zilungiswe nge-rivets wedge iron iron.

二, ukufakwa kwepuleti ephezulu

1, ngaphambi kokufaka ipuleti eliphezulu, uphahla kufanele lufakwe nge-t-iron ngokuya ngomdwebo. Lapho ufaka i-T-iron, i-T-iron kufanele ibekwe kahle ngokwesigaba sohlaka oluqinile ukuze uqinisekise ukuthi i-T-iron ayikhiqizi ukungcola phansi ngemuva kokufakwa kwepuleti ephezulu. Ukufakwa kwepuleti eliphakeme kufanele kuqale ekhoneni lomzimba we-warehouse, futhi ngokusho komdwebo weplate-waving, ipuleti yokugcina impahla kufanele likhuphukelwe ukuphakama okucacisiwe kanye nasekupheleni kwepuleti yokugcina impahla kufanele kubekwe ekhasini elidongeni kanye ne-t-iron ngokulandelana. Lungisa ukufana kanye ne-verticality yomugqa we-coaxial webhodi eliphakeme, buyekeza ukuphakama kwendawo engezansi yebhodi eliphakeme, bese ulungisa ibhodi ephezulu nge-t-iron nge-donsela ibhodi phakathi kwebhodi lodonga, bese uqala ukufakwa kwebhodi elilandelayo.

2, Indlela yesibili yokufaka ipuleti ephezulu ifana neplate yokuqala, indlela yokuxhuma ebhodini ngokuyisisekelo ngokufana nokufakwa kwepuleti yodonga. Ukuxhumeka kufanele kulungiswe ngaphandle kwendawo yokugcina impahla

3, ngemuva kokufakwa kwawo wonke amapuleti aphezulu, qala ukufakwa kophahla lwe-C-Beam. Ngokusho komugqa wangempela wepuleti ephezulu, emhlabathini kuzolungiswa amakhowe ekhanda le-nylon bolts angle izingcezu ngokuya ngezikhala ezihambisanayo zensimbi enophahla lwe-C-Shape ehambisanayo. Ngemuva kwalokho faka uphahla lwe-C-SAM ngesikhundla esihambisanayo sepuleti ephezulu ngokuya ngomdwebo, futhi u-C-Beam ophahleni kufanele aqinisekise ukufana kanye ne-verticity yomugqa we-coaxial. Ngemuva kokulungisa isikhundla sophahla lwe-C-BEAM, vula umgodi wepuleti eliphezulu esikhundleni se-bolt hole ye-angle pure puleti, bese uxhuma ucezu lwensimbi ye-angle ngekhanda lamakhowe le-nylon bolt. Ngemuva kwalokho, wehla ngophahla lwe-C-BEAM THE PURLIN ngensimbi ephethe insimbi eyindilinga, futhi ulungise i-nati ngaphansi kwe-pendant yensimbi eyindilinga ukuze ulungise i-C-Belate ebekwe phansi ngokulandela ukuphakama kwepuleti ephezulu.

三,ukufakwa kwebhodi ekhoneni

Onke amabhodi ekhoneni elibandayo avalwe uphawu lokunamathisela uphawu ngaphakathi kwezinhlangothi zombili nangokuxhumana neBhodi. Ukuqothuka kwamakhoneni phakathi kwamaphaneli odonga kufanele kulungiswe ezigabeni ukwenza lula ukuthulula kwe-polyurethane foam esizeni. IBhodi yeKoner ekhoneni eliphakeme lebhodi kufanele linqunywe njalo nge-500mm ngensimbi yokuvula (usayizi wokuvula ukuze ukwazi ukungena ezintweni zegwebu zizonqoba), bese zizolungiswa ebhodini eliphezulu kanye nebhodi leWall. IBHODI LOKWINI LOKWENZA LOKUQHAWULWA NGEMIBHALO ETHOLAKALAYO, NOKUXHUMANA NAMAHHALA phakathi kwama-rivets adonsayo kufanele kugcinwe ngo-100mm, kanti ama-rivets adonswa ekhoneni kufanele abe emgqeni oqondile onama-spacesing alinganayo. Naka ukumba kokumba kwama-rivets kanye nokusetshenziswa kwama-rivets ukulungisa ama-rivets, ithuluzi elisetshenzisiwe kufanele libe mpo nge-coner board.

Isikhathi Seposi: Meyi-23-2023